| Outer Diameter | Dikte fan de muorre | Gewicht | Klasse | Threaded | Lingte | |

| yn | mm | kg/m | lb/ft | |||

| 4 1/2" | 114.3 | 14.14-22.47 | 9.50-11.50 | J55/N80/P110/K55 | LTC/STC/BTC | R1/R2/R3 |

| 5" | 127 | 17.11-35.86 | 11.50-24.10 | J55/N80/P110/K55 | LTC/STC/BTC | R1/R2/R3 |

| 5 1/2" | 139.7 | 20.83-34.23 | 14.00-23.00 | J55/N80/P110/K55 | LTC/STC/BTC | R1/R2/R3 |

| 6 5/8" | 168.28 | 29.76-35.72 | 20.00-24.00 | J55/N80/P110/K55 | LTC/STC/BTC | R1/R2/R3 |

| 7" | 177.8 | 25.30-56.55 | 17.00-38.00 | J55/N80/P110/K55 | LTC/STC/BTC | R1/R2/R3 |

| 7 5/8" | 193.68 | 35.72-63.69 | 24.00-42.80 | J55/N80/P110/K55 | LTC/STC/BTC | R1/R2/R3 |

| 8 5/8" | 219.08 | 35.72-72.92 | 24.00-49.00 | J55/N80/P110/K55 | LTC/STC/BTC | R1/R2/R3 |

| 9 5/8" | 244.48 | 48.07-86.91 | 32.30-58.40 | J55/N80/P110/K55 | LTC/STC/BTC | R1/R2/R3 |

| 10 3/4" | 273.05 | 48.73-97.77 | 32.75-65.70 | J55/N80/P110/K55 | LTC/STC/BTC | R1/R2/R3 |

| 11 3/4" | 298.45 | 62.50-89.29 | 42.00-60.00 | J55/N80/P110/K55 | LTC/STC/BTC | R1/R2/R3 |

| 13 3/8" | 339.72 | 71.43-107.15 | 48.00-72.00 | J55/N80/P110/K55 | LTC/STC/BTC | R1/R2/R3 |

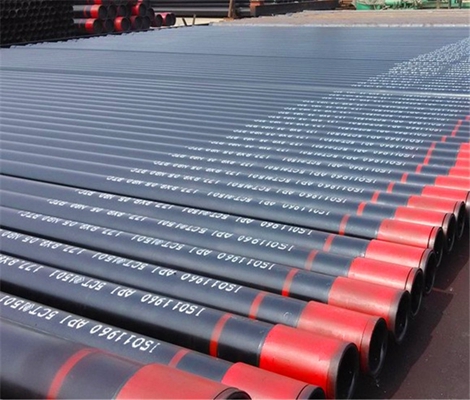

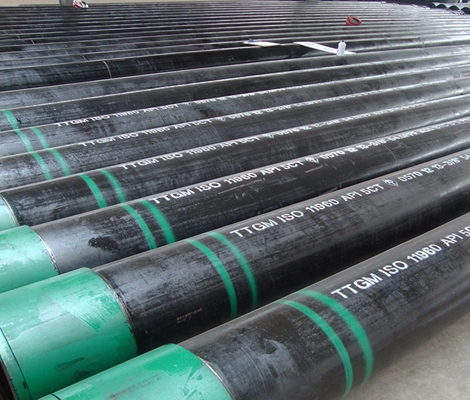

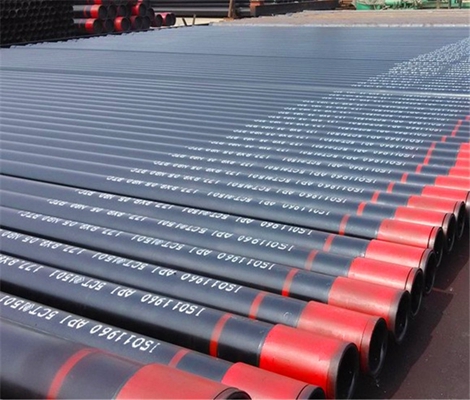

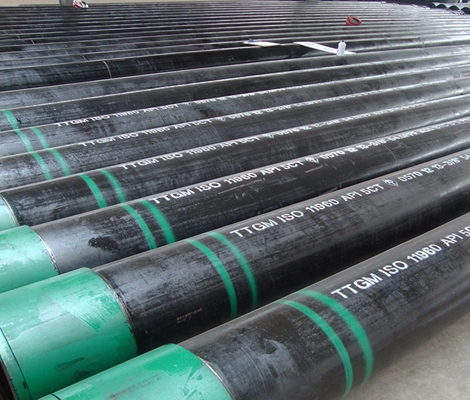

API 5CT J55 Casing Tubing Features

It oerflak fan tried fan coupling en API 5CT J55 Casing Tubing moat wêze glêd sûnder tear, burr

of oare mankeminten dy't meie hawwe in negative ynfloed op de sterkte en nauwe ferbining.

API 5CT J55 Casing Tubing wurdt oanbean mei in frije lingte berik fan 8m oant 13m op basis fan de SY/T6194-96

noarm. It is lykwols ek beskikber net minder as 6m lingte en syn kwantiteit moat net mear wêze as 20%.

Deformaasjes dy't hjirboppe neamd binne, binne net tastien op it bûtenste oerflak fan API 5CT J55 Casing

Tubing koppeling.

Elke deformaasje lykas kreuk, skieding, hierline, barst of skurfte is net akseptabel op sawol binnen as bûten

oerflak fan it produkt. Al dizze mankeminten moatte wurde folslein fuortsmiten, en de fuorthelle djipte moat net

mear as 12,5% fan nominale muorre dikte.

|

Standert |

Klasse |

Gemyske komponint (%) |

||||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

Als |

||

|

API SPEC 5CT |

J55K55 (37Mn5) |

0.34~0.39 |

0.20~0.35 |

1.25~1.50 |

≤0.020 |

≤0,015 |

≤0,15 |

≤0,20 |

≤0,20 |

≤0.020 |

||

|

N80 (36 Mn2V) |

0.34~0.38 |

0.20~0.35 |

1.45~1.70 |

≤0.020 |

≤0,015 |

≤0,15 |

0.11~0.16 |

≤0.020 |

||||

|

L80(13Cr) |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0,010 |

12.0~14.0 |

≤0,20 |

≤0,20 |

≤0.020 |

|||

|

P110, (30CrMo) |

0.26~0.35 |

0.17~0.37 |

0.40~0.70 |

≤0.020 |

≤0,010 |

0.80~1.10 |

≤0,20 |

≤0,20 |

0.15~0.25 |

≤0,08 |

≤ |

|

|

Standert |

Klasse |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Ferlinging (%) |

Hurdens |

|

API SPEC 5CT |

J55 |

≥517 |

379~552 |

/ |

|

|

K55 |

≥517 |

≥655 |

|||

|

N80 |

≥689 |

552~758 |

|||

|

L80(13Cr) |

≥655 |

552~655 |

≤241HB |

||

|

P110 |

≥862 |

758~965 |