EN10025-6 S620QL1 equivalent, EN10025-6 S620QL1 lamina ferrea, EN10025-6 S620QL1 ferrum equivalens, EN10025-6 S620QL1 chemica compositio, EN10025-6 S620QL1 materia

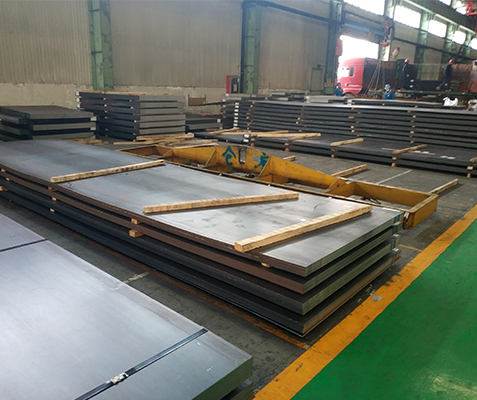

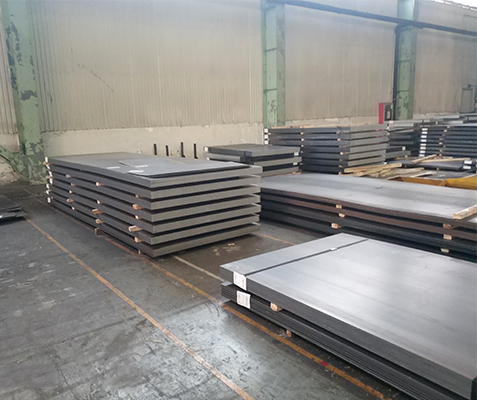

Lamina chalybis S620QL1 exstincta et temperata quae in EN 10025-6 condiciones technicae traditionis planae productorum altae cedunt roboris structuris ferreis in QT conditionis partus. The chalybe processus faciendi bracteae altae roboris S620QL1 erit secundum EN 10025-1. Si certo tempore ordinis ferrum processus faciendi emptori referatur. Humilis temperatus impactus experimentum altitudinis roboris ferreae S620QL1 ad minus 60 centigradum fieri debet.

Technical Requisita & Additional Services:

Low temperatus impacting test

Exstingui et Temperans curatio caloris

Ultrasonic test sub EN 10160,ASTM A435,A577,A578

Molendinum testium originale edita sub EN 10204 FORMAT 3.1/3.2

Iaculata inspiratione et Painting, Cutting et welding sicut per finem postulata usoris

EN10025-6 S620QL1 Lamellae chemicae compositionis chalybis temperatae et temperatae

| Gradus | C % | Si% | Mn% | P % | S % | N% | B % | Cr% |

| S620QL1 | 0.200 | 0.800 | 1.700 | 0.020 | 0.010 | 0.015 | 0.005 | 1.500 |

| Cu% | Mo% | Nb% | Ni% | Ti% | V % | Zr% | ||

| 0.500 | 0.700 | 0.060 | 2.000 | 0.050 | 0.120 | 0.150 |

EN10025-6 S620QL1 lamella chalybea temperata et temperata proprietatibus mechanicis

| Gradus | Crassitudo (mm) | Min Cede (Mpa) | Distrahens (MPa) | Prolongatio (%) | Min Impact Energy | |

| S620QL1 | 8mm-50mm | Min 620Mpa | 700-890Mpa | 15% | -60 | Min 30J |

| 51mm-100mm | Min 580Mpa | 700-890Mpa | 15% | -60 | Min 30J | |

| 101mm-150mm | Min 560Mpa | 650-830Mpa | 15% | -60 | Min 30J |

Si quid opus est in EN10025-6 S620QL1 lamina ferro extincta et temperata, placet liberum contactus nos.