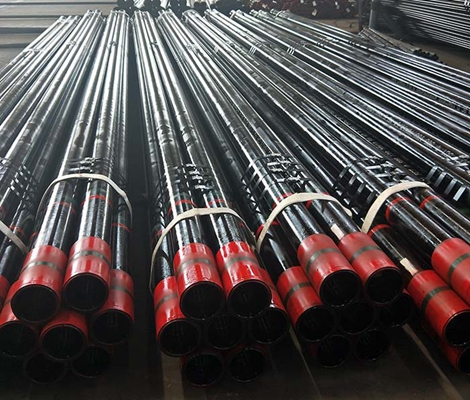

Spesifikasi Tiub Selongsong API 5CT J55

| Saiz Selongsong Paip, Saiz Selongsong Medan Minyak & Saiz Drift Selongsong | |

| Diameter Luar (Saiz Paip Selongsong) | 4 1/2"-20", (114.3-508mm) |

| Saiz Sarung Standard | 4 1/2"-20", (114.3-508mm) |

| Jenis Benang | Selongsong benang penopang, Selongsong benang bulat panjang, Selongsong benang bulat pendek |

| Fungsi | Ia boleh melindungi paip tiub. |

Ciri-ciri Tiub Selongsong API 5CT J55

Permukaan benang gandingan dan Tiub Selongsong API 5CT J55 hendaklah licin tanpa sebarang koyak, burr atau kecacatan lain

yang mungkin memberi kesan negatif terhadap kekuatan dan hubungan rapat.

Tiub Selongsong API 5CT J55 ditawarkan dengan julat panjang percuma dari 8m hingga 13m berdasarkan norma SY/T6194-96. Walau bagaimanapun,

ia juga boleh didapati tidak kurang daripada 6m panjang dan kuantitinya hendaklah tidak melebihi 20%.

Ubah bentuk yang dinyatakan di atas tidak dibenarkan muncul pada permukaan luar gandingan Tiub Selongsong API 5CT J55.

Sebarang ubah bentuk seperti lipatan, pemisahan, garis rambut, retak atau kudis tidak boleh diterima pada kedua-dua permukaan dalam dan luar produk.

Semua kecacatan ini harus dibuang sepenuhnya, dan kedalaman yang dikeluarkan tidak boleh melebihi 12.5% daripada ketebalan dinding nominal.

| Saiz | Berat badan | Diameter Luar | Ketebalan dinding | Tamat Tamat | ||

| Gred | ||||||

| dalam | mm | dalam | mm | J55 K55 |

||

| 4 1/2 | 9.50 | 4.500 | 114.3 | 0.205 | 5.21 | PS |

| 10.50 | 0.224 | 5.69 | PSB | |||

| 11.60 | 0.250 | 6.35 | PSLB | |||

| 13.50 | 0.290 | 7.37 | – | |||

| 15.10 | 0.337 | 9.56 | – | |||

| 5 | 11.50 | 5.00 | 127.00 | 0.220 | 5.59 | PS |

| 13.00 | 0.253 | 6.43 | PSLB | |||

| 15.00 | 0.296 | 7.52 | PSLB | |||

| 18.00 | 0.362 | 9.19 | – | |||

| 21.40 | 0.437 | 11.10 | – | |||

| 23.20 | 0.478 | 12.14 | – | |||

| 24.10 | 0.500 | 12.70 | – | |||

| 5 1/2 | 14.00 | 5.500 | 139.7 | 0.244 | 6.20 | PS |

| 15.50 | 0.275 | 6.98 | PSLB | |||

| 17.00 | 0.304 | 7.72 | PSLB | |||

| 20.00 | 0.361 | 9.17 | – | |||

| 23.00 | 0.415 | 10.54 | – | |||

| 6 5/8 | 20.00 | 6.625 | 168.28 | 0.288 | 7.32 | PSLB |

| 24.00 | 0.352 | 8.94 | PSLB | |||

| 28.00 | 0.417 | 10.59 | – | |||

| 32.00 | 0.475 | 12.06 | – | |||

| 7 | 17.00 | 7.00 | 177.80 | 0.231 | 5.87 | – |

| 20.00 | 0.272 | 6.91 | PS | |||

| 23.00 | 0.317 | 8.05 | PSLB | |||

| 26.00 | 0.362 | 9.19 | PSLB | |||

| 29.00 | 0.408 | 10.36 | – | |||

| 32.00 | 0.453 | 11.51 | – | |||

| 35.00 | 0.498 | 12.65 | – | |||

| 38.00 | 0.540 | 13.72 | – | |||

| 7 5/8 | 24.00 | 7.625 | 193.68 | 0.300 | 7.62 | – |

| 26.40 | 0.328 | 8.33 | PSLB | |||

| 29.70 | 0.375 | 9.52 | – | |||

| 33.70 | 0.430 | 10.92 | – | |||

| 39.00 | 0.500 | 12.70 | – | |||

| 42.80 | 0.562 | 14.27 | – | |||

| 45.30 | 0.595 | 15.11 | – | |||

| 47.10 | 0.625 | 15.88 | – | |||

| 8 5/8 | 24.00 | 8.625 | 219.08 | 0.264 | 6.71 | PS |

| 28.00 | 0.304 | 7.72 | – | |||

| 32.00 | 0.352 | 8.94 | PSLB | |||

| 36.00 | 0.400 | 10.16 | PSLB | |||

| 40.00 | 0.450 | 11.43 | – | |||

| 44.00 | 0.500 | 12.70 | – | |||

| 49.00 | 0.557 | 14.15 | – | |||

| 9 5/8 | 32.30 | 9.625 | 244.48 | 0.312 | 7.92 | – |

| 36.00 | 0.352 | 8.94 | PSLB | |||

| 40.00 | 0.395 | 10.03 | PSLB | |||

| 43.50 | 0.435 | 11.05 | – | |||

| 47.00 | 0.472 | 11.99 | – | |||

| 53.50 | 0.545 | 13.84 | – | |||

| 58.40 | 0.595 | 15.11 | – | |||

| 10 3/4 | 32.75 | 10.75 | 273.05 | 0.279 | 7.09 | – |

| 40.50 | 0.350 | 8.89 | PSB | |||

| 15.50 | 0.400 | 10.16 | PSB | |||

| 51.00 | 0.450 | 11.43 | PSB | |||

| 55.50 | 0.495 | 12.57 | – | |||

| 60.70 | 0.545 | 13.84 | – | |||

| 65.70 | 0.595 | 15.11 | – | |||

| 13 3/8 | 48.00 | 13.375 | 339.73 | 0.330 | 8.38 | – |

| 54.50 | 0.380 | 9.65 | PSB | |||

| 61.00 | 0.430 | 10.92 | PSB | |||

| 68.00 | 0.480 | 12.19 | PSB | |||

| 72.00 | 0.514 | 13.06 | – | |||

| 16 | 65.00 | 16 | 406.40 | 0.375 | 9.53 | – |

| 75.00 | 0.438 | 11.13 | PSB | |||

| 84.00 | 0.495 | 12.57 | PSB | |||

| 109.00 | 0.656 | 16.66 | P | |||

| 18 5/8 | 87.50 | 18.625 | 473.08 | 0.435 | 11.05 | PSB |

| 20 | 94.00 | 20 | 508.00 | 0.438 | 11.13 | PSLB |

| 106.50 | 0.500 | 12.70 | PSLB | |||

| 133.00 | 0.635 | 16.13 | PSLB | |||

Keperluan Tegangan & Kekerasan

| Gred | taip | Pemanjangan total di bawah beban % |

Kekuatan hasil MPa | Kekuatan tegangan min. MPa | Kekerasan maks. | Dinding yang ditentukan ketebalan mm |

Kekerasan yang dibenarkan variasi b HRC |

||

| min. | maks | HRC | HBW | ||||||

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - |