Corrugated Steel Sheet

Corrugated Steel Sheet is also called corrugated sheet. It is made of metal sheets such as color-coated steel sheets and galvanized sheets, which are rolled and cold-bent into various corrugated sheets. It is suitable for industrial and civil buildings, warehouses, special buildings, roofs, walls, and interior and exterior wall decoration of large-span steel structures. It has the characteristics of light weight, high strength, rich colors, convenient and fast construction, earthquake resistance, fire resistance, rain resistance, long life, and maintenance-free.

Manufacturing process

Manufacturing process

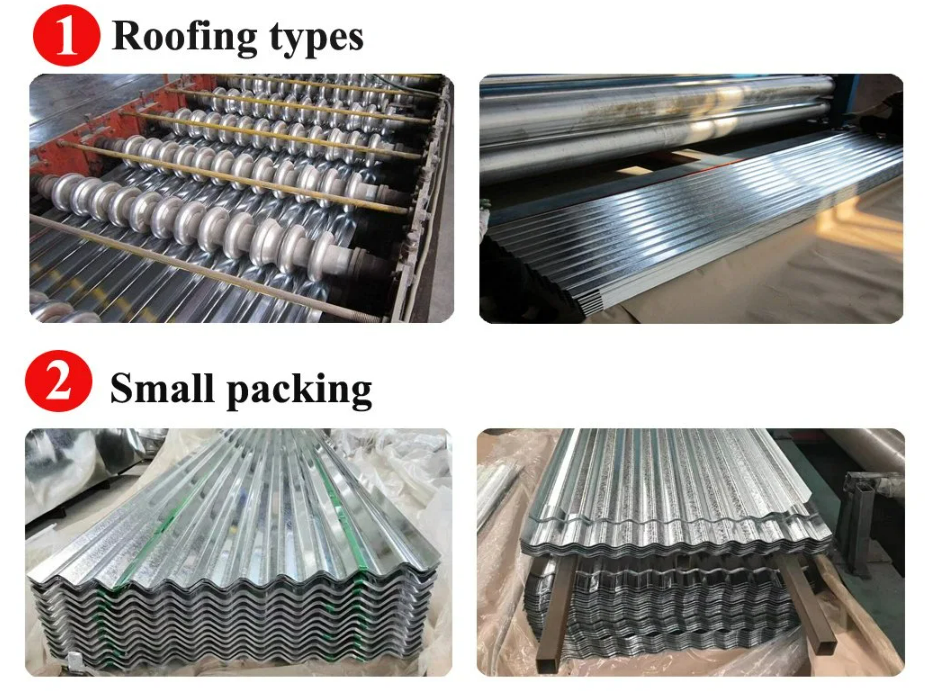

1. Forming: After cold rolling or hot rolling, the steel sheet is formed into a wavy shape by forming equipment.

2. Corrugated design: The corrugated shape can be different designs, including V-shaped, U-shaped, triangle, etc., each design has different uses and aesthetic effects.

3. Surface treatment: The surface of the steel sheet may be treated with anti-corrosion treatment, such as hot-dip galvanizing, to improve corrosion resistance.

The corrugated structure of the corrugated sheet can be divided into different peaks and troughs, which helps to enhance the strength, rigidity and stability of the material.

Features and Benefits

1. Strength and rigidity: The corrugated design increases the strength and rigidity of the steel sheet, making it more resistant to external pressure and loads.

2. Lightweight: Despite its high strength, corrugated steel sheets are relatively light, making them easier to transport, handle and install in buildings.

3. Aesthetics: The corrugated shape not only provides additional strength to the steel sheet, but also gives the building a more distinctive and aesthetic appearance.

4. Corrosion resistance: If surface treatments are applied, such as hot-dip galvanizing, corrugated steel sheets can better resist corrosion and extend their service life.

Application areas

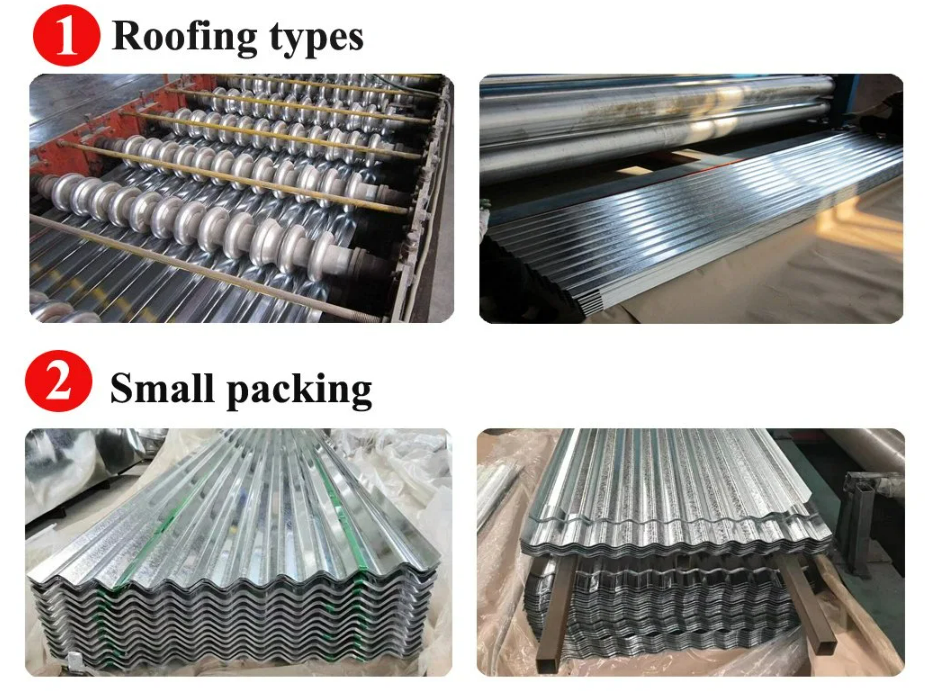

1. Construction: Covering materials for roofs and walls, providing structural strength and waterproofing.

2. Storage facilities: Used to manufacture warehouses, sheds, open-air shelves, etc.

3. Transportation: Used to manufacture carriages for light vehicles, such as container trucks.

4. Agricultural uses: Used to manufacture agricultural buildings, such as farmhouses, livestock sheds, etc.

5. Temporary buildings: Used as covering material for simple houses or temporary buildings in the wild during outdoor activities.