Halabuurka kiimikada ee heerka JB / T 6057-92 birta (jajab tiro,%)

| C |

Si |

Mn |

P |

S |

Ni |

Cr |

Cu |

| 0.17~0.23 |

0.17~0.37 |

0.35~0.65 |

≤0.035 |

≤0.035 |

≤0.30 |

≤0.25 |

≤0.25 |

Guryaha makaanikada

(5) Heerkulka marxaladda kala guurka (qiimaha qiyaastii) Ac1=735℃, Ac3=855℃, Ar3=835℃, Ar1=680℃

(6) Tilmaamaha Caadiga ah Heerkulka waa 920 ~ 950 ℃, foornadana waa hawo la qaboojiyey. Adaggu waa 131 ~ 156HBS.

(7) Tilmaamaha loogu talagalay jilicsanaanta daawaynta meelaha banaan ee qabow Heerkulka waa 700 ~ 720 ℃, wakhtiga haynta waa 8 ~ 15h, iyo heerka qaboojinta waa 50 ~ 100 ℃ / h, iyo heerkulku hoos ugu dhaco 550 ~ 600 ℃ foornada, foornadana hawo qaboojiso.

Adag daawaynta ka hor waa ≤143HBS, iyo adayga ka dib marka la jilciyo waa ≤131HBS.

(8) Deminta qeexitaanka heerkulka 910 ℃ ± 10 ℃, ku qaboojinta 10% NaCl brine.

(9) Awood dhalidda la qiyaasay fy=245Mpa, elastic modules E=206Gpa, saamiga Poisson

(10) Xoogga dhogorta waa 275 ~ 392MPa, xoogga xajintu waa 253 ~ 500MPa, xoogga dhalidda waa 275MPa, dhererkuna waa 25%.

(11) Heerkulka annealing waa kaliya 600-650 digrii, iyo waqtiga haynta waa 1-2h.

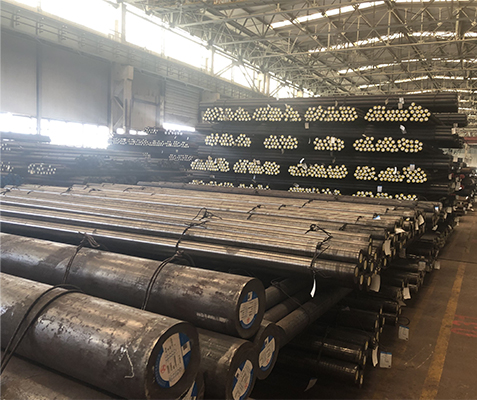

Adeegyadayada ee bar-wareegayada:

1. Haddii aad hesho dhibaato tayo leh ka dib markaad alaabta hesho, waad nala soo xidhiidhi kartaa, waxaanu maamulaynaa oo aanu kuugu jawaabi doonaa 12 saacadood gudahood

2.Waxaan nahay warshad soo saarta SS Round bar, kartida wax soo saarka ugu fiican, xakamaynta tayada ugu fiican, Adeegga ugu Wanaagsan.

3.Waxaa kormeeray machadka Kormeerka SGS ama ISO

4.100% Kormeerka QC Kahor Soo Dejinta.

Haddii aad wax su'aalo ah qabtid Fadlan nala soo xiriir waqtiga saxda ah.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)