| Ukwakhiwa Kwekhemikhali (%) | ||||||||

| Ibanga Lensimbi | C | Si | UMn | P | S | Cr | Ni | Cu |

| 35CrMnSiA | 0.32-0.39 | 1.10~1.40 | 0.80~1.10 | ≤0.025 | ≤0.025 | 1.10~1.40 | ≤0.030 | ≤0.025 |

| Amandla okukhiqiza σs/MPa (>=) | Amandla okuqina σb/MPa (>=) | Amandla okuthinta | Ukuncishiswa kwe indawo ψ/% (>=) |

Umthelela omunca amandla αkv (J/cm²) (>=) |

| ≥1275(130) | ≥1620(165) | ≥31 | ≥40 | ≥39(4) |

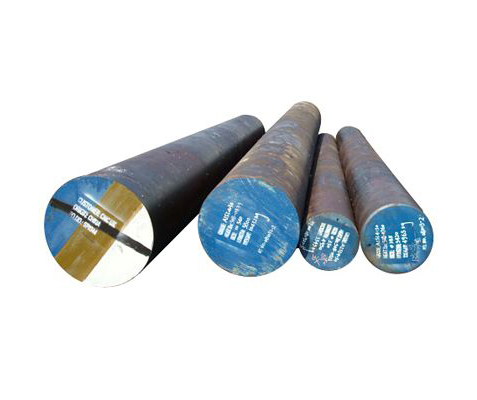

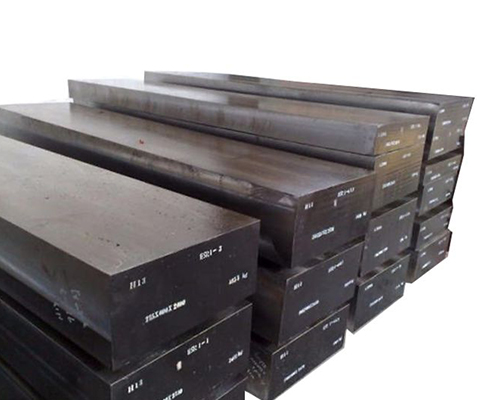

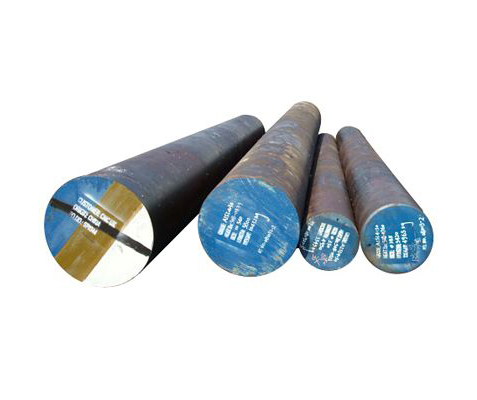

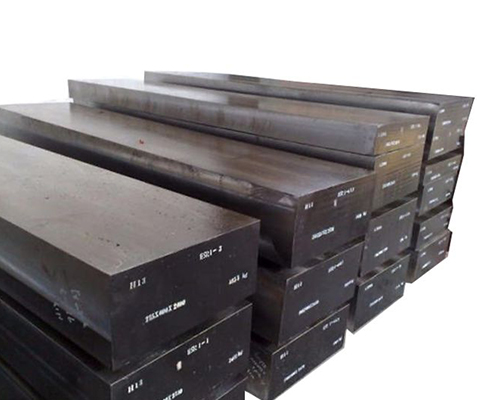

I-GB/T 11251 35CrMnSiA amapuleti ensimbi agingqiwe ashisayo ensimbi ye-Gnee asetshenziswa kabanzi ukwenza isivinini esiphakathi nendawo, umthwalo osindayo, amandla aphezulu, izingxenye eziqinile eziphakeme kanye nezingxenye zamandla aphezulu. I-Gnee steel izimisele ukuba umphakeli wakho othembekile we-35CrMnSiA hot rolled alloy steel plates.

I-Gnee Steel igxile kakhulu ku-GB/T 11251 35CrMnSiA amapuleti ensimbi agingqiwe ashisayo angaphansi kokucaciswa kwe-GB/T.GB/T 11251 35CrMnSiA amapuleti ensimbi agingqiwe ashisayo anezakhiwo ezinhle kakhulu zokusebenza nokusebenza kabanzi. Ukuhlanganisa izinzuzo ezingenhla kunganikezwa kakhulu ngokuhambisana nemikhiqizo yezidingo zekhasimende. Ngaphezu kwalokho, sizohlinzeka ngokusika, ukwelapha kusengaphambili, ukufaka umpheme, ukuhlola, izinsizakalo zokwelashwa kokushisa kwe-GB/T 11251 35CrMnSiA amapuleti ensimbi agingqiwe ashisayo.