Ntinye ngwaahịa

35CrMnSiA bụ igwe nwere obere alloy nwere ike dị elu. Mgbe okpomọkụ ọgwụgwọ, ọ nwere ezi keukwu n'ibu Njirimara, elu ike, zuru ezu toughness, hardenability, weldability (preheating tupu ịgbado ọkụ), na nhazi formability, ma ọ nwere ezi corrosion eguzogide na Low ọxịdashọn eguzogide, n'ozuzu na-eji mgbe ala okpomọkụ tempering ma ọ bụ austempering. Nchara arụrụ arụ nke siri ike menyụọ na ọkụ. Ọ nwere ike dị elu na ike siri ike, ike siri ike dị elu, ọkara oyi nrụrụ plasticity, yana ịrụ ọrụ nke ọma. Enwere ọchịchọ nke iwe ọkụ, na mmetụta siri ike nke ntụgharị adịghị mma. The ịgbado ọkụ arụmọrụ ka mma, ma mgbe ọkpụrụkpụ bụ ukwuu karịa 3mm, ọ ga-preheated ka 150 ℃ mbụ, na okpomọkụ ọgwụgwọ a chọrọ mgbe ịgbado ọkụ. A na-ejikarị ya eme ihe mgbe iwe ọkụ gasịrị.

Ebumnuche dezie

A na-eji 35CrMnSiA na-emepụta ngwa ngwa ngwa ngwa, ọrụ dị arọ, ike dị elu, akụkụ siri ike na ihe ndị dị ike.

A na-ejikarị emepụta akụkụ dị iche iche dị mkpa nke nwere nnukwu ibu na nnukwu ọsọ dị elu, dị ka gia, shafts, clutches, sprockets, wheel shafts, bushings, bolts, nuts, wdg. arụ ọrụ okpomọkụ na mgbanwe ibu. Ihe ndị welded dị ka eriri ikuku na-eku ume dị elu, efere valve na ọkpọkọ na-adịghị emebi emebi

Data teknụzụ

|

Ngwakọta kemịkalụ (%) |

| Ọkwa ígwè |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Ku |

| 35CrMnSiA |

0.32-0.39 |

1.10~1.40 |

0.80~1.10 |

≤0.025 |

≤0.025 |

1.10~1.40 |

≤0.030 |

≤0.025 |

Ngwa igwe

| Ike mpụta σs /MPa (>=) |

Ike tensile σb/MPa (>=) |

Mmetụta ike |

Mbelata

mpaghara ψ/% (>=) |

Mmetụta nnabata ike αkv (J/cm²) (>=) |

| 1275 (130) |

1620 (165) |

≥31 |

≥40 |

≥39 (4) |

Nkọwapụta ọgwụgwọ okpomọkụ na nhazi metallographic

Nkọwa ọgwụgwọ okpomọkụ: (1) Quenching: mbụ 950 ℃, nke abụọ 890 ℃, mmanụ jụrụ oyi; tempering 230 ℃, ikuku jụrụ, mmanụ jụrụ; (2) 880 ℃ austempering na 280 ~ 310 ℃.

Ekwesịrị ịkọwa ọkwa nnyefe na nkwekọrịta mgbe a na-enye ya site na ọgwụgwọ okpomọkụ (normalizing, annealing or high okpomọkụ tempering) ma ọ bụ na-enweghị ọgwụgwọ okpomọkụ.

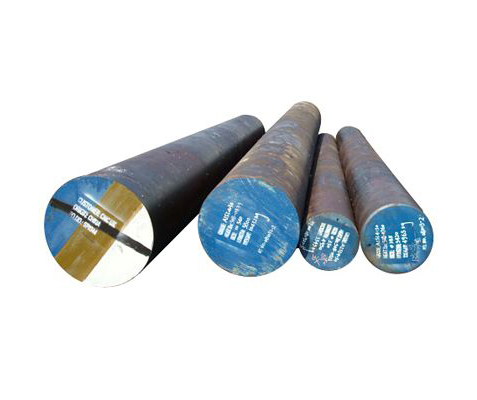

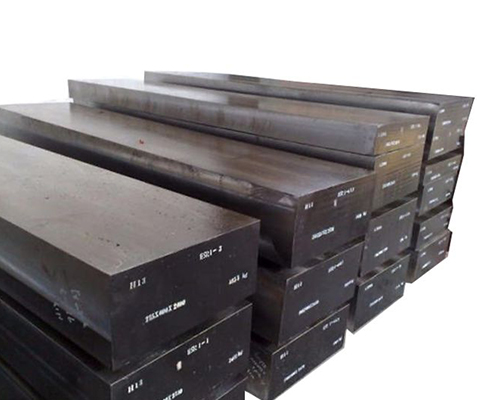

GB/T 11251 35CrMnSiA na-ekpo ọkụ akpọrepu Ọdịdị ígwè efere nke Gnee ígwè na-ọtụtụ ebe na-eji rụpụta ọkara ọsọ, arọ ibu, elu ike, elu toughness akụkụ na elu ike components. Gnee steel dị njikere ịbụ onye 35CrMnSiA nke a pụrụ ịdabere na ya ka ọ bụrụ onye na-ebubata efere alloy na-ekpo ọkụ.

Gnee Steel bụ ọkachamara na GB / T 11251 35CrMnSiA na-ekpo ọkụ akpọrepu Ọdịdị ígwè efere nke dị n'okpuru GB/T specification.GB/T 11251 35CrMnSiA na-ekpo ọkụ akpọrepu Ọdịdị ígwè efere nwere magburu onwe n'ibu Njirimara na n'ọtụtụ ebe ngwa. Ijikọta uru dị n'elu nwere ike ịnye nke kachasị na ngwaahịa ndị ahịa chọrọ. Ọzọkwa, anyị ga-enye ịcha, pretreatment, galvanizing, ule, okpomọkụ ọgwụgwọ ọrụ maka GB/ T 11251 35CrMnSiA ọkụ akpọrepu Ọdịdị ígwè efere.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)