Product introduction

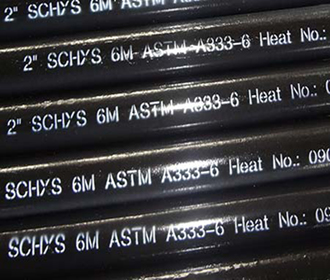

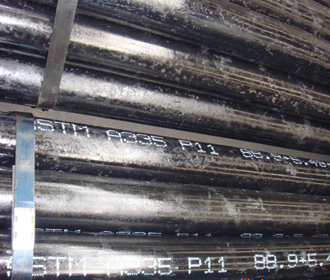

SA333 Gr.6 is a specification for low-temperature carbon steel seamless pipes, which are used in various applications, including industrial and commercial applications as well as in the oil and gas industry. The "SA" in SA333 stands for "Specification for ASME (American Society of Mechanical Engineers) A/SA-333."The Gr.6 in SA333 Gr.6 represents the grade of steel used in the specification, which has a low carbon content and contains small amounts of other elements like manganese and silicon, making it ideal for use in low-temperature environments.

SA333 Gr.6 seamless steel pipes are produced using a seamless manufacturing process, which involves piercing a solid billet of steel to create a hollow tube. The seamless construction provides higher strength and durability compared to welded pipes.These seamless pipes are used in various low-temperature service applications, such as in the transportation of liquefied natural gas (LNG) and other cryogenic liquids. They are also used in other industries, such as chemical processing and power generation.

Steel pipe dimensional deviation and weight deviation

Outer diameter deviation: The outer diameter deviation of the steel pipe shall meet the requirements

| Diameter range(mm) |

10.3~48.3 |

>48.3~114.3 |

>114.3~219.1 |

>219.1~406.4 |

| Diameter deviation(mm) |

-0.8~+0.4 |

-0.8~+0.8 |

-0.8~+1.6 |

-0.8~+2.4 |

Wall thickness deviation: -8% ~ + 12%.

Weight deviation: -3.5% ~ + 10%.

Fixed-length accuracy: according to user requirements.

Straightness: ≤1.5mm / m.

Delivery status and heat treatment process of steel pipe

The steel pipe is delivered in the normalized heat treated state.

The normalized heat treatment process of the finished product is: 900 ° C ~ 930 ° C for 5 ~ 15min, air cooling.

Impact performance

Each batch of steel pipes with an outer diameter greater than 21.3mm shall be inspected for impact performance Akv.

| Specimen thickness(mm) |

|

3 |

3.3 |

4 |

5 |

6 |

6.67 |

7 |

7.5 |

8 |

9 |

10 |

| Akv(J) |

≥

5 |

≥

6 |

≥

7 |

≥

8 |

≥

9 |

≥11 |

≥

12 |

≥13 |

≥

14 |

≥16 |

≥17 |

≥18 |

Impact test temperature

When the thickness of the small-sized impact specimen reaches or exceeds 80% of the actual thickness of the steel pipe, the test temperature is -45 ° C.

When the thickness of the small-sized impact specimen is less than 80% of the actual thickness of the steel pipe, the specimen thickness should be as large as possible. The test temperature was -55 ° C.

Hardness test (only when required by the contract)

If the contract requires the hardness to be tested in accordance with the NACE MR-0175 standard, a test piece of approximately 20-30 mm in length shall be taken from each batch of steel pipes, and the hardness shall be less than 22HRc.