| Element | Weight Percentage |

| Titanium (Ti) | 99.2% min |

| Iron (Fe) | 0.3% max |

| Oxygen (O) | 0.25% max |

| Carbon (C) | 0.1% max |

| Nitrogen (N) | 0.03% max |

| Hydrogen (H) | 0.015% max |

| Other Elements | 0.4% max total |

| Material Equivalents | Related Specifications |

| UNS R50400 | ASTM B338 |

| Grade 2 | ASTM B861 |

| Ti-Pure® Grade 2 | ASTM F67, ASTM F467 |

| DIN 3.7035 | ISO 5832-2 |

| JIS H 4600 Grade 2 |

It's important to note that while these materials have similar chemical compositions and properties, there may be slight variations in their performance depending on the specific manufacturing processes and conditions. Therefore, it's important to choose the appropriate material for the specific application and consult with the relevant standards and specifications.

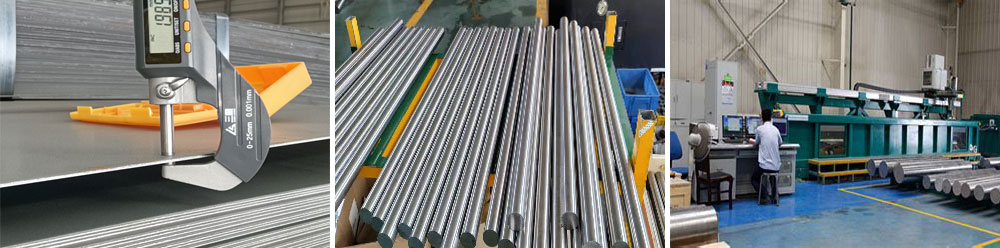

Melting: The first step in producing titanium tubes is melting the titanium sponge, which is a high-purity form of titanium metal. This is typically done using an electric arc furnace or a vacuum arc melting process.

Ingot Casting: The molten titanium is then poured into molds to produce titanium ingots.

Hot Extrusion: The titanium ingots are heated and then extruded through a die to form a long tube with a uniform cross-section.

Cold Rolling: The titanium tube is then cold rolled to reduce its diameter and thickness to the desired size and shape.

Annealing: The titanium tube is then heat-treated in an annealing furnace to improve its ductility, toughness, and resistance to corrosion.

Straightening: The titanium tube is straightened to ensure that it is free of any twists or bends that could affect its performance.

Cutting: The titanium tube is cut to the desired length using a saw or other cutting tool.

Inspection: The titanium tube is inspected to ensure that it meets the required specifications and standards for its intended application.

Finishing: The titanium tube may undergo additional finishing processes, such as polishing or cleaning, before being packaged and shipped to the customer.