Chemical Composition of Gr5 Titanium Pipe Material

| Element |

Weight Percentage |

| Titanium (Ti) |

88.61 - 90.82% |

| Aluminum (Al) |

5.50 - 6.75% |

| Vanadium (V) |

3.50 - 4.50% |

| Iron (Fe) |

0.25% maximum |

| Oxygen (O) |

0.20% maximum |

| Carbon (C) |

0.08% maximum |

| Nitrogen (N) |

0.05% maximum |

| Hydrogen (H) |

0.015% maximum |

Gr5 Titanium Pipe Material Equivalent and Related Speciation

| Material Equivalents |

Related Specifications |

| Ti-6Al-4V |

ASTM B338, ASTM B861, AMS 4928, AMS 4911, AMS 4967, MIL-T-9047G, AMS-T-81915, ISO 5832-3, ASTM F1472 |

| Grade 5 Titanium |

ASME SB-338, ASME SB-861, AMS 4928, AMS 4911, AMS 4967, MIL-T-9047G, AMS-T-81915, ISO 5832-3, ASTM F1472 |

| TA6V |

EN 10204, EN 10216-5, EN 10253-3, EN 10297-2, EN 10305-1, EN 10305-2, EN 10305-3, EN 10305-4, EN 10305-5 |

It's important to note that these are just a few examples of the many material equivalents and related specifications for Gr5 titanium tubes. The exact specification or equivalent material used will depend on the specific application and requirements.

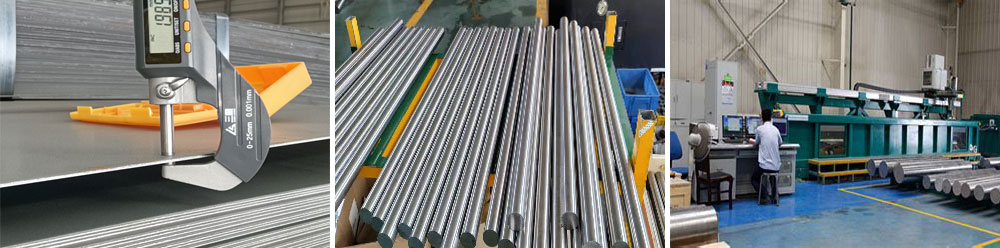

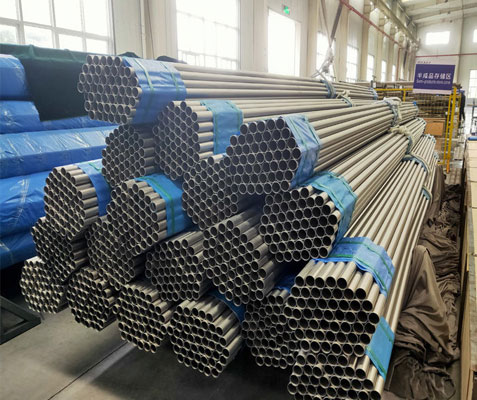

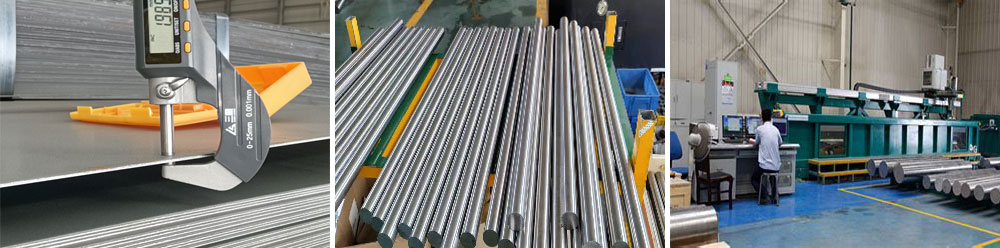

There are several quality inspection methods that can be used for Gr5 titanium tubes to ensure their quality and performance. Some common methods include:

Visual inspection: This involves examining the surface of the tube for defects such as cracks, scratches, or surface irregularities.

Dimensional inspection: This involves measuring the diameter, wall thickness, and length of the tube to ensure that they meet the specified tolerances.

Ultrasonic testing: This method uses high-frequency sound waves to detect any internal defects in the tube, such as cracks or voids.

Eddy current testing: This method uses an electromagnetic field to detect any surface or subsurface defects in the tube, such as cracks or corrosion.

X-ray or radiographic testing: This method uses X-rays to inspect the tube for internal defects, such as voids, cracks, or inclusions.

Positive material identification (PMI): This method uses spectroscopy to identify the chemical composition of the tube and ensure that it meets the specified requirements.

Hydrostatic testing: This involves pressurizing the tube with water to test its strength and ability to withstand pressure.

These quality inspection methods can be used individually or in combination depending on the specific requirements of the application and the industry standards. It is important to ensure that the quality inspection methods used are appropriate for the specific type of Gr5 titanium tube and the intended use.