Tlhaloso ea Sehlahisoa

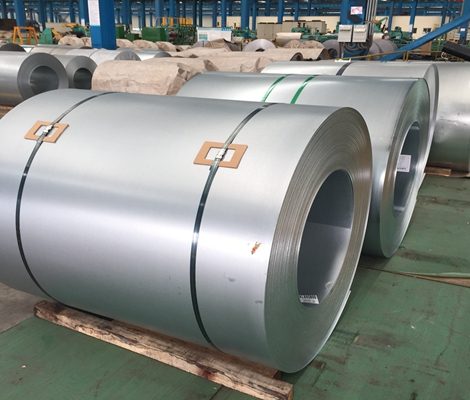

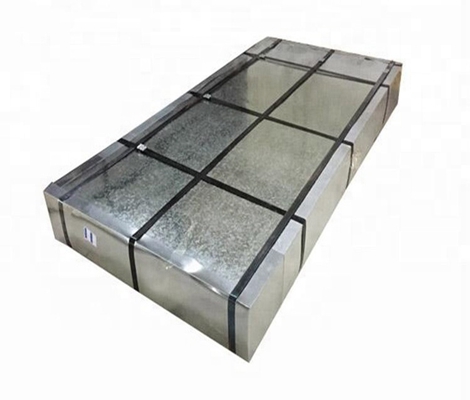

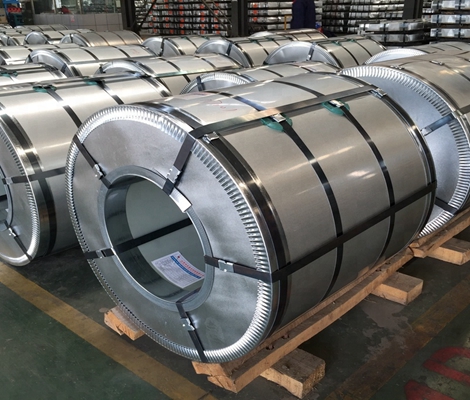

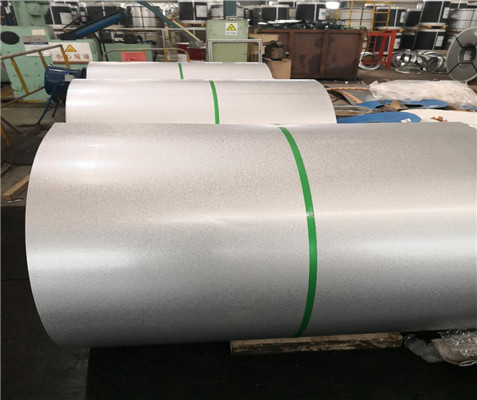

Electro galvanizing, eo hape e tsejoang ka hore ke serame se pholileng indastering, ke mokhoa oa ho etsa junifomo, tšepe e teteaneng le e kopantsoeng hantle kapa lesela la alloy deposition holim'a lihlahisoa ka electrolysis.

Electroplated galvanized sheet, e hlahisoang ke mokhoa oa electroplating, e na le ts'ebetso e ntle. Leha ho le joalo, barbotage e tšesaane 'me ho hanyetsa ha eona ha ho joalo hantle joaloka lakane e chesang ea dip galvanized;

Seccn2 ke mofuta oa poleiti ea tšepe e sa sireletsehang ea menoana ea menoana.

| lebitso la sehlahisoa |

SECCN2 Galvanized Sel Coil |

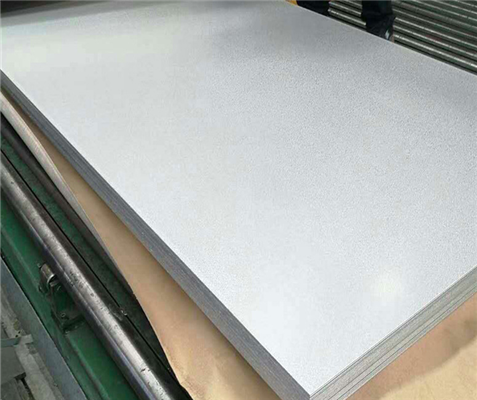

| Botenya |

0.13mm-5.0mm |

| Bophara |

600mm-1500mm,762mm,914mm,1000mm,1200mm,1219mm,1250mm |

| zinki |

40g, 60g, 80g |

| Standard |

ASTM, AISI, DIN, GB |

| Lintho tse bonahalang |

SECCN2 |

| Spangle |

Tloaelehileng spangle |

| Kalafo e ka holimo |

e nang le chromated le oli, chromated le non oil |

| Ho paka |

theolelo ea thepa. |

| Tefo |

T/T, L/C kapa DP |

| min otara |

Lithane tse 25 (e le 'ngoe 20ft FCL) |

Lintlha tse ling

Melemo ea Sehlahisoa

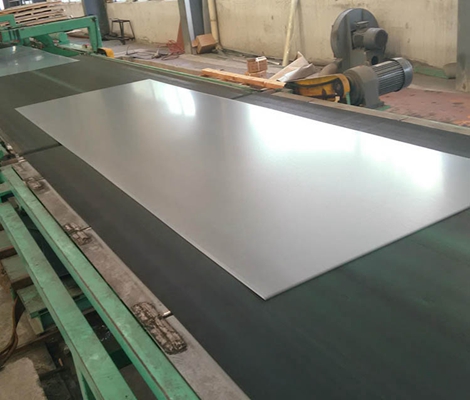

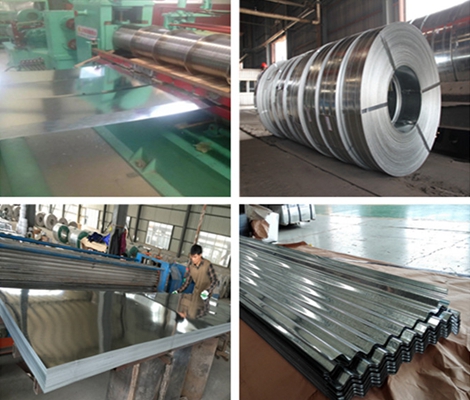

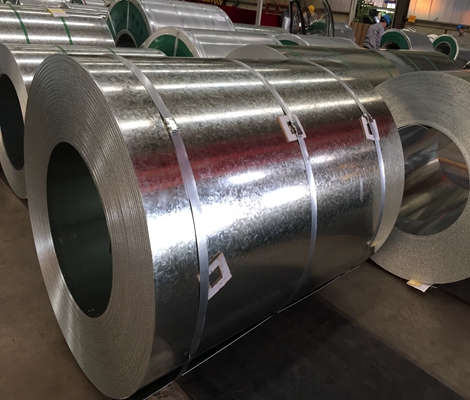

1.Continuous Galvanization

Ho Sebelisa Mahlale a Phethahetseng ke Lilemo tsa Boiphihlelo, Letlapa la Ts'epe le Chesang la GNEE la Dip le Thehiloe Moleng o Tsoelang Pele o Lokisetsa ho Tiisa Lihlahisoa tse Boreleli, tsa boleng bo holimo.

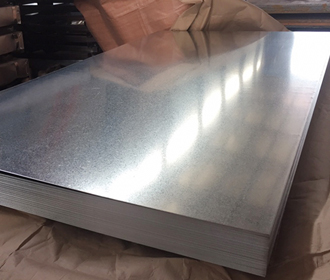

Ts'epe ea GNEE e Ikemiseditse ho Fana ka Leqephe la Sesetile le Nang le Mefuta e Pharalletseng ea Litšobotsi tsa Metal tsa Base, tse kenyeletsang Khoebo, Ho Theha Lock, Drawing, le Boleng ba Sebopeho. Ho feta moo, Sehlahisoa se seng le se seng se Etsa Ts'ebetso ea Chromatic Bakeng sa Tšireletso Khahlanong le Rust.

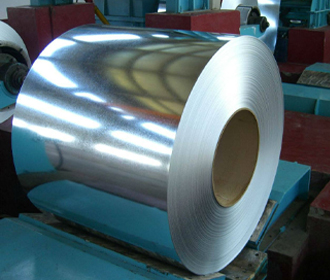

2.Superior Formability

Leqephe le Lithapa Tse Sebeletsang Haholo Li sebelisoa e le Litšepe Tsa Botlaaseng Bakeng sa Leqephe Tsohle la Setsi le Hlahisitsoeng Setsing sa Cold Rolling sa Dingang Steel. Litšepe tsa Base ho Coil li lula li eketsoa, li tšeloa ka matla, 'me li behiloe hantle. Leqephe la Galvanized le Fana ka Formability e Phahameng ka ho Fetisisa ka Metals ea Base.

3.E babatsehang Corrosion Resistance

Leqephe lohle la Galvanized Steel le Alafshoa ka Acid ea Chromic Bakeng sa Tšireletso Khahlanong le Rust, Ho Boloka Letlapa la Pele la Bokaholimo ka Nako e teletsana.

4.Consistent Quality

Tlhahiso e Etsoa ho Sebelisa Mokhoa o Tiileng oa Taolo ea Boleng le Tlhahlobo e Thata ea Boleng e Thehiloe ho Maemo a Phahameng a Tlhahiso. Ka lebaka leo, Boleng ba Sehlahisoa, Botekanyo, Le Thepa e Meng e Lumellana ka Thata le Tlhoko ea Bareki.

Litšobotsi

1.ho hanyetsa ho bola ho matla

2.boleng ba sefahleho

3.conducive to deep processing, joalo ka letlapa la masenke

4.moruo le ts'ebetsong

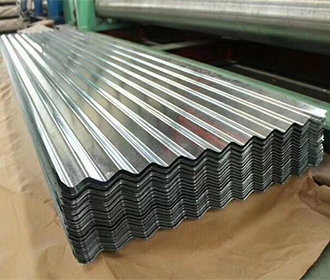

Kopo

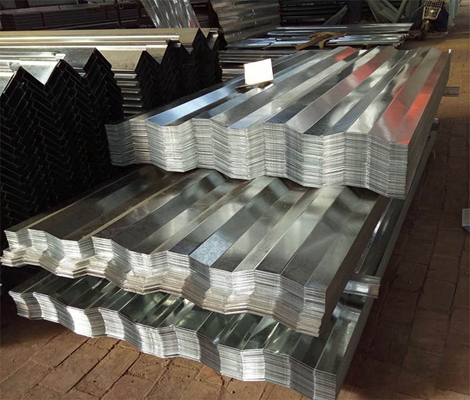

Marulelo le mabota, liprofaele tse kobehileng, masenke a koahetsoeng ka mapolanka, marulelo le mabota, lithaele tsa marulelo, likhoele tsa metsi a pula, mamati a tšepe, mamati a karache, likaroloana tsa mabota, liphanele tsa siling, liforeimi tse emisitsoeng, mamati a tšepe a kahare kapa lifensetere, lintlha tsa likhabinete tsa kantle tsa lisebelisoa tse tšoeu, thepa ea ka tlung ea ofisi.

.jpg)

.jpg)

.jpg)

.jpg)