Ukubunjwa kweekhemikhali zomgangatho we-JB / T 6057-92 yentsimbi (iqhekeza elikhulu,%)

| C |

Si |

Mnu |

P |

S |

Ni |

Cr |

Cu |

| 0.17~0.23 |

0.17~0.37 |

0.35~0.65 |

≤0.035 |

≤0.035 |

≤0.30 |

≤0.25 |

≤0.25 |

Iimpawu zoomatshini

(5) Iqondo lotshintsho lwenqanaba (ixabiso eliqikelelweyo) Ac1=735℃, Ac3=855℃, Ar3=835℃, Ar1=680℃

(6) Ubume besiqhelo Ubushushu bungama-920 ~ 950℃, kwaye isithando somlilo sipholile. Ubunzima buyi-131 ~ 156HBS.

(7) Ukucaciswa kokuthambisa unyango lweendawo ezicinezelekileyo ezibandayo Ubushushu yi-700 ~ 720 ℃, ixesha lokubamba ngu-8 ~ 15h, kwaye izinga lokupholisa liyi-50 ~ 100 ℃ // h, kwaye ubushushu buhla ukuya kwi-550 ~ 600 ℃ kunye neziko, kwaye iziko lipholiswa ngumoya.

Ubunzima phambi kokuba unyango ≤143HBS, kwaye ubunzima emva kokuthambisa ≤131HBS.

(8) Ukucima iinkcukacha zoBubushushu 910℃±10℃, ukupholisa nge-10% ye-NaCl brine.

(9) Umlinganiselo wamandla esivuno fy=245Mpa, imodyuli elastiki E=206Gpa, umlinganiselo wePoisson ν=0.3.

(10) Amandla okucheba ngama-275 ~ 392MPa, amandla e-tensile yi-253 ~ 500MPa, amandla emveliso yi-275MPa, kwaye ubude ngama-25%.

(11) Ukushisa kwe-anneal yi-600-650 degrees kuphela, kwaye ixesha lokubamba li-1-2h.

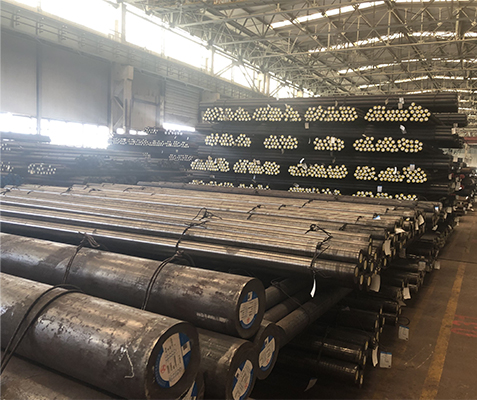

Iinkonzo zethu zebar yethu engqukuva :

1. Ukuba ufumana nayiphi na ingxaki yomgangatho emva kokufumana iimpahla, ungaqhagamshelana nathi, siya kulawula kwaye sikuphendule kwiiyure eziyi-12.

2.Singumzi-mveliso we-SS Round bar, eyona mveliso inamandla, ulawulo olungcono lomgangatho, Inkonzo eYona .

3.Ihlolwe liziko lokuhlola le-SGS okanye i-ISO

4.100% Ukuhlolwa kwe-QC phambi kokuThunyelwa.

Ukuba unombuzo, Nceda uqhagamshelane nathi ngexesha.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)