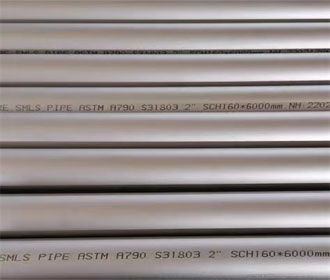

ASTM Stainless Steel Pipe

ASTM Stainless Steel Pipe refers to stainless steel pipes that comply with the standards set by the American Society for Testing and Materials (ASTM). These pipes are manufactured using high-quality stainless steel materials and undergo rigorous testing to ensure their quality and performance. ASTM standards for stainless steel pipes cover various aspects such as dimensions, material composition, mechanical properties, and testing methods. They provide guidelines for seamless and welded pipes used in a wide range of industries, including petrochemical, chemical, oil and gas, pharmaceutical, food processing, power generation, and construction.

| ASTM Stainless Steel Pipe |

|

| Grade |

304, 304L, 316, 316L, 317L, 321, 347, 310S, 904L, SAF 2205, SAF 2507, 254 SMO, etc. |

| Standard |

ASTM A312, ASTM A358, ASTM A269, ASTM A213, etc. |

| Material |

Austenitic, Duplex, Super Duplex Stainless Steel |

| Features |

Excellent corrosion resistance, high temperature resistance, superior strength, good weldability, wide range of sizes and wall thicknesses, low maintenance, long service life |

| Applications |

Petrochemical industry, chemical industry, oil and gas industry, pharmaceutical industry, food processing, power generation, pulp and paper industry, water treatment, architectural structures, automotive, marine, etc. |

| Grade |

Chemical Composition |

Features and Applications |

| 304 |

C: ≤ 0.08%, Mn: ≤ 2.00%, P: ≤ 0.045%, S: ≤ 0.030%, Cr: 18-20%, Ni: 8-10.5% |

Excellent general corrosion resistance, good formability, and weldability. Widely used in various industries and architectural applications. |

| 304L |

C: ≤ 0.03%, Mn: ≤ 2.00%, P: ≤ 0.045%, S: ≤ 0.030%, Cr: 18-20%, Ni: 8-12% |

Low carbon variant of 304 with improved weldability. Suitable for welding applications and environments with sensitization concerns. |

| 316 |

C: ≤ 0.08%, Mn: ≤ 2.00%, P: ≤ 0.045%, S: ≤ 0.030%, Cr: 16-18%, Ni: 10-14%, Mo: 2-3% |

Enhanced corrosion resistance, particularly against chlorides and acidic environments. Commonly used in marine and chemical industries. |

| 316L |

C: ≤ 0.03%, Mn: ≤ 2.00%, P: ≤ 0.045%, S: ≤ 0.030%, Cr: 16-18%, Ni: 10-14%, Mo: 2-3% |

Low carbon variant of 316 with improved weldability and resistance to sensitization. Suitable for welding applications and corrosive environments. |

| 317L |

C: ≤ 0.03%, Mn: ≤ 2.00%, P: ≤ 0.045%, S: ≤ 0.030%, Cr: 18-20%, Ni: 11-15%, Mo: 3-4% |

Higher molybdenum content for enhanced resistance to pitting and crevice corrosion. Suitable for corrosive environments and chemical processing. |

| 321 |

C: ≤ 0.08%, Mn: ≤ 2.00%, P: ≤ 0.045%, S: ≤ 0.030%, Cr: 17-19%, Ni: 9-12%, Ti: 5xC-0.70% |

Stabilized with titanium to prevent sensitization and intergranular corrosion. Suitable for high-temperature applications and heat exchangers. |

| 347 |

C: ≤ 0.08%, Mn: ≤ 2.00%, P: ≤ 0.045%, S: ≤ 0.030%, Cr: 17-19%, Ni: 9-13%, Nb: 10xC-1.10% |

Stabilized with niobium to prevent sensitization and intergranular corrosion. Used in high-temperature applications and corrosive environments. |

| 310S |

C: ≤ 0.08%, Mn: ≤ 2.00%, P: ≤ 0.045%, S: ≤ 0.030%, Cr: 24-26%, Ni: 19-22% |

Excellent resistance to high temperatures and oxidation. Used in heat treatment furnaces, radiant tubes, and other high-temperature applications. |

| 904L |

C: ≤ 0.02%, Mn: ≤ 2.00%, P: ≤ 0.045%, S: ≤ 0.035%, Cr: 19-23%, Ni: 23-28%, Mo: 4-5% |

High alloy austenitic stainless steel with exceptional corrosion resistance in a wide range of environments. Used in severe corrosive conditions. |

| SAF 2205 |

C: ≤ 0.03%, Mn: ≤ 2.00%, P: ≤ 0.030%, S: ≤ 0.020%, Cr: 22-23%, Ni: 4.5-6.5%, Mo: 3-3.5%, N: 0.14-0.20% |

Duplex stainless steel with high strength and excellent resistance to chloride stress corrosion cracking. Suitable for offshore and marine applications. |

| SAF 2507 |

C: ≤ 0.03%, Mn: ≤ 1.20%, P: ≤ 0.035%, S: ≤ 0.020%, Cr: 24-26%, Ni: 6-8%, Mo: 3-5%, N: 0.24-0.32% |

Super duplex stainless steel with superior corrosion resistance, high strength, and excellent resistance to pitting and crevice corrosion. Used in aggressive environments. |

| 254 SMO |

C: ≤ 0.020%, Mn: ≤ 1.00%, P: ≤ 0.030%, S: ≤ 0.010%, Cr: 19.5-20.5%, Ni: 17.5-18.5%, Mo: 6-6.5%, Cu: 0.5-1.0%, N: 0.18-0.22% |

High-performance stainless steel with excellent resistance to corrosion, particularly in acidic chloride-containing environments. Used in chemical and offshore industries. |

Multi-Grade Stainless Steel Pipe:

ASTM Stainless Steel Pipe grades also include 201,301,301L, 316Ti, 321, 409,410, 410L,410S,430,436L,439, 441,etc.

.jpg)

FAQ:

1.Are you a manufacturer?

Yes, we are a steel manufacturer for 16 years. Our factory is in Anyang. We provide production, processing and customization services for various steel raw materials.

2. How do you guarantee your quality?

Before cooperation, we can provide you with free samples, quality inspection certificates, different national standard certificates, and also take you to visit our factory for personal inspection. Don't worry, just contact us.

3.What's the difference between you and others?

As you can see,we are a manufacturer,we promise to provide you with the lowest price and guaranteed quality.

We have our own ASTM stainless steel pipe processing machine to process any size as clients requirements.

We have 60000 tons of regular specification in stock for delivery within 7 days.For customer order, production time is 15-30 workdays after receiving the deposit.

Our own packing team can make sure best export standard packing for goods without any damage.

And our own warehouse and transport fleet can promise goods send to port on time.

4. How can I get the price of needed product?

It's the best way if you can send us the material, size and surface, so we can produce for you and check the quality.If you still

have any confusion, just contact us, we would like to be helpful.

5. Is it OK to print my logo on products?

Sure, we can provide OEM and ODM services. You just need to prepare your logo and tell us,we will get it.

Quality Inspection:

.jpg)

(2).jpg)

.jpg)

.jpg)