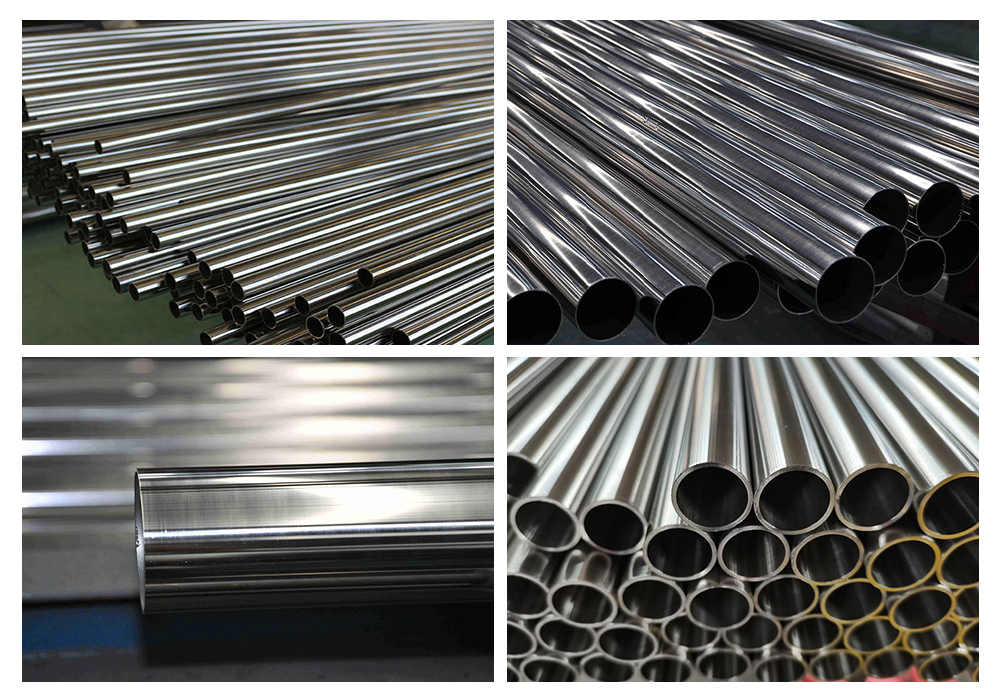

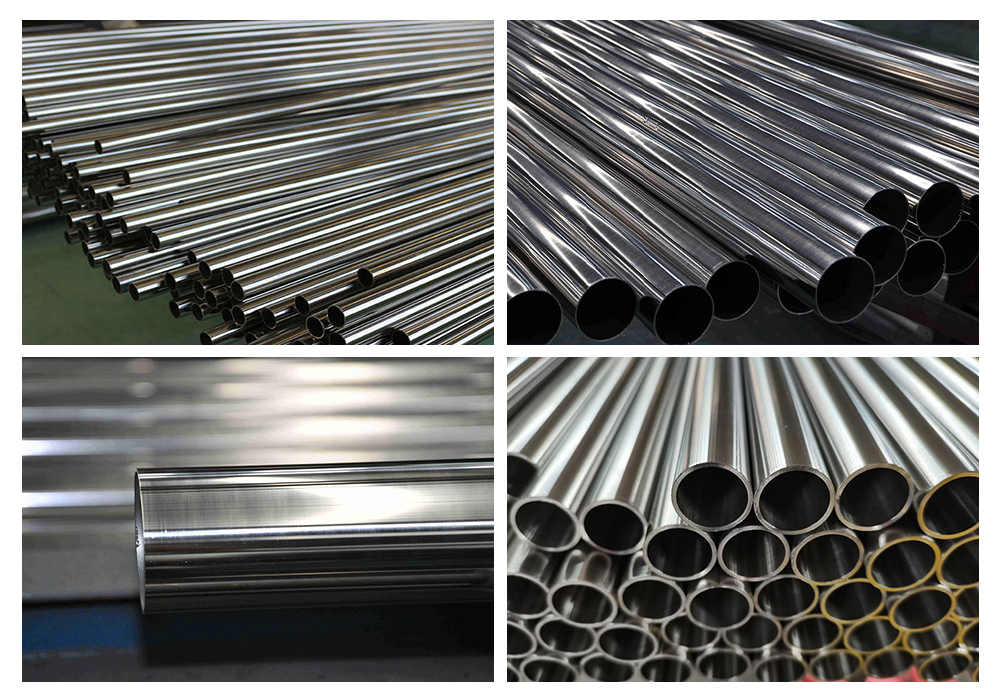

Wholesale Stainless Steel Pipe

As a well-known stainless steel pipe wholesaler and manufacturer, GNEE Corporation is committed to producing and supplying superior quality stainless steel pipe products. We offer a wide selection of stainless steel tube sizes and dimensions to meet the needs of different industries and applications. Whether you need a large diameter tube or a small diameter tube, we can provide customized solutions to ensure that the product is perfectly matched to the project requirements.

| Grade Designation |

Characteristics |

Applications |

| 304 Stainless Steel |

Corrosion-resistant, excellent formability, and weldability. |

Food processing, chemical processing, architectural uses. |

| 316 Stainless Steel |

Superior corrosion resistance, especially in chloride or acidic environments. |

Marine, pharmaceutical, chemical processing industries. |

| 321 Stainless Steel |

Stabilized against chromium carbide formation, resistant to intergranular corrosion. |

High-temperature applications, heat exchangers, aerospace components. |

| 409 Stainless Steel |

Excellent resistance to exhaust gas and atmospheric corrosion. |

Automotive applications, exhaust systems. |

| 410 Stainless Steel |

Good corrosion resistance, high strength. |

Valves, pump parts, moderate corrosion-resistant applications. |

| Duplex Stainless Steel (e.g., 2205) |

Combines ferritic and austenitic properties, high strength, excellent corrosion resistance, good weldability. |

Oil and gas industry, chemical processing, offshore structures. |

| 904L Stainless Steel |

High-alloy austenitic stainless steel, excellent acid resistance, particularly sulfuric acid. |

Chemical processing, pharmaceuticals, seawater desalination. |

Multi-Grade Stainless Steel Pipe:

Stainless steel tube grades also include 201, 202, 304, 304L, 316, 316L, 310, 2205, 317L, 904L, 316Ti, 430, 316LN, 347, 446, 2507, 15-5 PH, 17-4 PH, and Nitronic 50.

Quality Inspection:

Mechanical property testing: Through testing methods such as tensile test, impact test and hardness test, the mechanical properties of stainless steel tubes, such as tensile strength, yield strength, elongation and impact toughness, are evaluated.

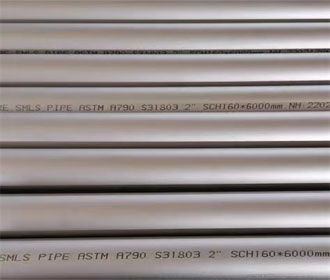

Dimensional inspection: By measuring the dimensional parameters such as outer diameter, wall thickness and length of the stainless steel pipe to ensure that they are in line with the specified dimensional requirements.

Surface inspection: The surface of the stainless steel tube is inspected, including observation of the presence of cracks, scars, oxidation, corrosion and other defects, which are evaluated and classified.

Corrosion testing: The corrosion resistance of stainless steel tubes in specific corrosive environments is evaluated using appropriate corrosion test methods, such as salt spray testing, corrosive media immersion, etc.

Non-destructive testing: use nondestructive testing methods, such as ultrasonic testing, radiographic testing, magnetic particle testing, etc., to detect defects such as cracks, inclusions, etc., that exist inside the stainless steel tube.

.jpg)

.jpg)

.jpg)

.jpg)