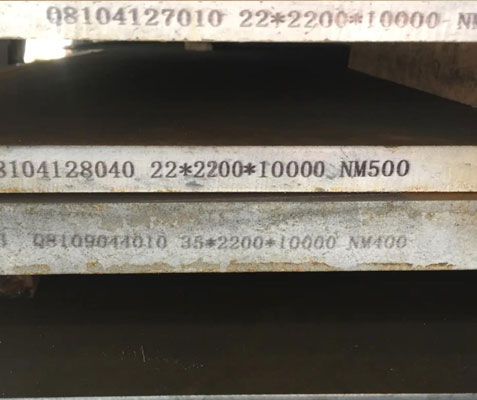

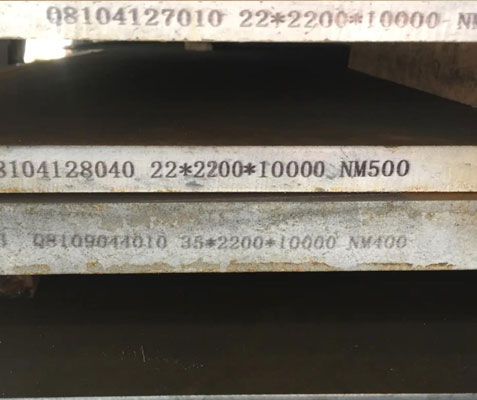

GB/T24186 NM500 abrasion resistant steel plate is an abrasion resistant plate with a hardness of 500 HBW. intended for applications where demands are mposed on abrasion resistance in combination with good cold bending properties. GB/T24186 NM500 abrasion resistant steel plate offers very goodweldability.

GB/T24186 NM500 abrasion resistant steel plate is a high-strength wear-resisting steel plate, which has a high abrasion resistance. Brinell hardness value up to 500(HBW) is mainly used to provide protection for wear-resisting occasions or parts, so as to prolong the service life of the equipment, reduce the maintenance and stop caused by maintenance, and correspondingly reduce the investment of funds.

| Specifications | GB/T24186 NM500 abrasion resistant steel plate |

| Standard | GB/T24186 |

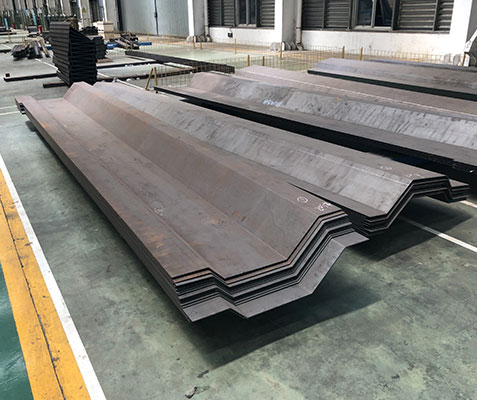

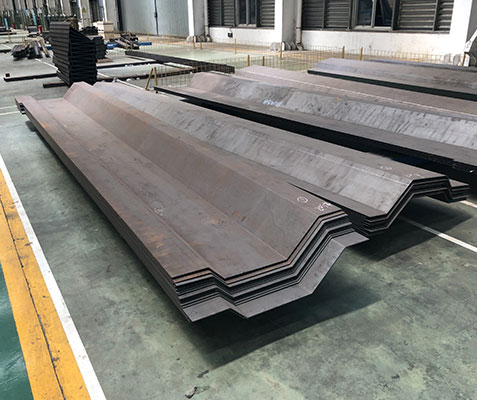

| Specialize | Shim Sheet, Perforated Sheet, B. Q. Profile. |

| Length | 50mm-18000mm |

| Width | 50mm-4020mm |

| Thickness | 1.2mm-300mm |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

Profiled: According to drawing.

Inspection: Chemical analysis, Metallographic, Mechnical analysis, Ultrasonic testing, Impact testing, Hardness testing, Surface quality and Dimension report.

MOQ: 1pcs.

Supplementary Technology: Brinell hardness, HBW according to EN ISO 6506-1, on a milled surface 0,5–2 mm below plate surface per heat and 40 tons. Tests are made for every variation of 15 mm in the thickness of plates from the same heat.

| Brand | C | Si | Mn | P | S | Cr | Mo | Ni | B | CEV |

| NM360 | ≤0.17 | ≤0.50 | ≤1.5 | ≤0.025 | ≤0.015 | ≤0.70 | ≤0.40 | ≤0.50 | ≤0.005 | |

| NM400 | ≤0.24 | ≤0.50 | ≤1.6 | ≤0.025 | ≤0.015 | 0.4~0.8 | 0.2~0.5 | 0.2~0.5 | ≤0.005 | |

| NM450 | ≤0.26 | ≤0.70 | ≤1.60 | ≤0.025 | ≤0.015 | ≤1.50 | ≤0.05 | ≤1.0 | ≤0.004 | |

| NM500 | ≤0.38 | ≤0.70 | ≤1.70 | ≤0.020 | ≤0.010 | ≤1.20 | ≤0.65 | ≤1.0 | Bt: 0.005-0.06 | 0.65 |

| Brand | Thickness mm | Tensile Test MPa | Hardness | |||||||

| YS Rel MPa | TS Rm MPa | Elongation % | ||||||||

| NM360 | 10-50 | ≥620 | 725-900 | ≥16 | 320-400 | |||||

| NM400 | 10-50 | ≥620 | 725-900 | ≥16 | 380-460 | |||||

| NM450 | 10-50 | 1250-1370 | 1330-1600 | ≥20 | 410-490 | |||||

| NM500 | 10-50 | --- | ---- | ≥24 | 480-525 | |||||

Capacity: 3,000 ton per month.

Test: Chemical analysis, Metallographic, Mechnical analysis, Ultrasonic testing, Impact testing, Hardness testing, Surface quality and Dimension report.

Package: Bundle or piece.

Mill’s Test Certificate

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.

Heat treatment: quenching and tempering (quenching and tempering).

NM500 wear-resistant steel is widely used construction machinery, mining machinery, mining machinery, environmental protection machinery, metallurgical machinery, abrasives, bearings and other product components.