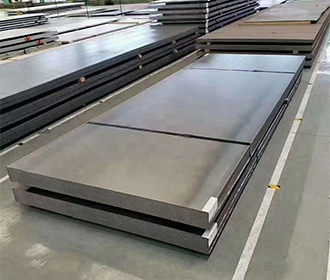

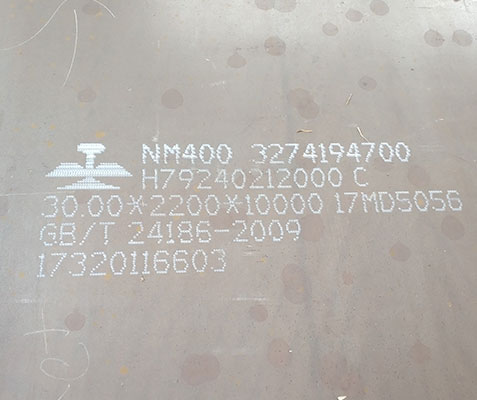

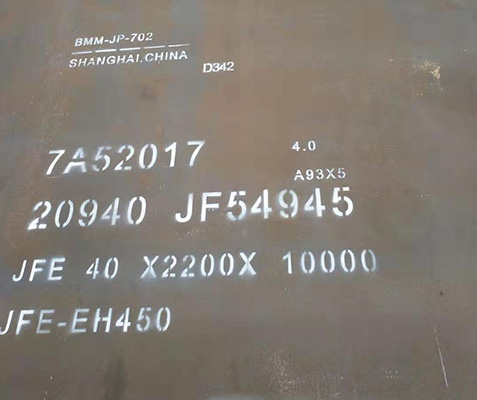

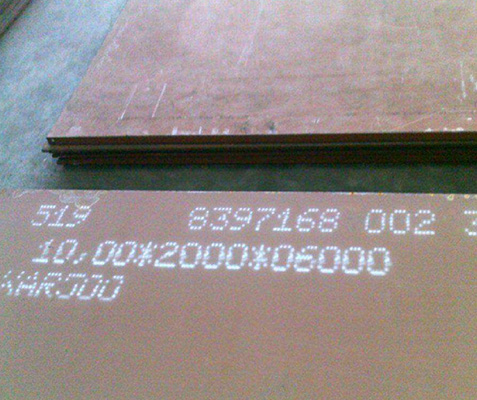

Products list

Gnee steel,steel supply from sky to sea are available,global reachable;

Contact us

Address: FLAT/RM 1512 15/F LUCKY CENTRE NO.165-171 WAN CHAI ROAD WAN CHAI HK

.jpg)

.jpg)

.jpg)

.jpg)