Awọn ọja akojọ

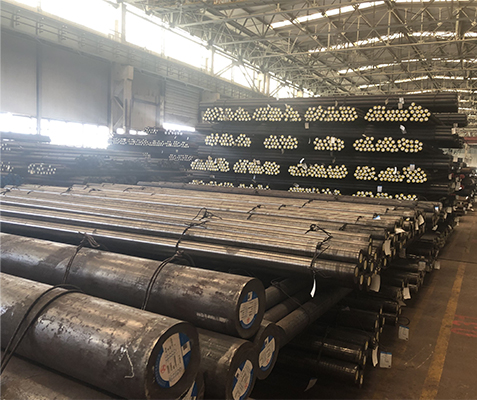

Gnee irin, irin ipese lati ọrun si okun wa o si wa, agbaye arọwọto;

Pe wa

Adirẹsi: No.. 4-1114,Beichen Building,Beicang Town,Beichen District Tianjin,China.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)