Alloy 347 is a balanced, austenitic, chromium steel containing columbium which takes into consideration the end of carbide precipitation, and thus intergranular corrosion. Alloy 347 is balanced out by the increases of chromium and tantalum and offers higher creep and stress rupture properties than alloy 304 and 304L, which may also be utilized for exposures where sensitization and intergranular corrosion are of concern.The expansion of columbium likewise permits Alloy 347 to have outstanding corrosion resistance, better than that of alloy 321. Alloy 347H is the higher carbon composition form of Alloy 347and display enhanced high temperature and creep properties.

Characteristics

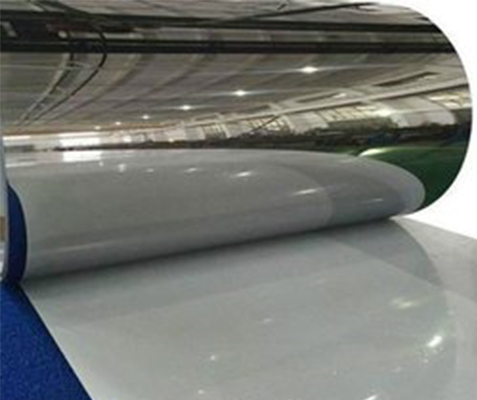

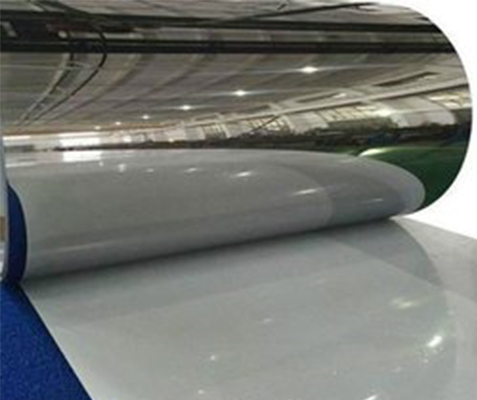

Alloy 347 stainless steel plate displays good general corrosion resistance that is similar to 304. It was produced for use in the chromium carbide precipitation scope by 800 – 1500°F (427 – 816°C) where unbalanced alloys such as 304 are subject to intergranular attack. In this temperature scope, the overall corrosion resistance of Alloy 347 stainless steel plate is better than Alloy 321 stainless steel plate. Alloy 347 additionally performs somewhat superior to Alloy 321 in strongly oxidizing situations up to 1500°F (816°C). The alloy can be utilized as a part of nitric solutions; most diluted organic acids at moderate temperatures and in pure phosphoric acid at lower temperatures and up to 10% diluted solutions at high temperatures. Alloy 347 stainless steel plate resists polythionic acid stress corrosion cracking in hydrocarbon service. It can also be used in chloride or fluoride free caustic solutions at moderate temperatures. Alloy 347 stainless steel plate doesn't perform well in chloride solutions, even in small concentrations, or in sulfuric acid.

| Grade | C | Si | P | S | Cr | Mn | Ni | Fe | Cb (Nb+Ta) |

| 347 | 0.08 max | 0.75 max | 0.045 max | 0.03 max | 17.0 - 19.0 | 2.0 max | 9.0-13.0 | Remainder | 10x (C + N)- 1.0 |

| 347H | 0.04-0.10 | 0.75 max | 0.045 max | 0.03 max | 17.0 - 19.0 | 2.0 max | 9.0-13.0 | Remainder | 8x (C + N)- 1.0 |

| Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

| 75 | 30 | 40 |

| Units | Temperature in °C | |

| Density | 7.97 g/cm³ | Room |

| Specific Heat | 0.12 Kcal/kg.C | 22° |

| Melting Range | 1398 - 1446 °C | - |

| Modulus of Elasticity | 193 KN/mm² | 20° |

| Electrical Resistivity | 72 µΩ.cm | Room |

| Coefficient of Expansion | 16.0 µm/m °C | 20 - 100° |

| Thermal Conductivity | 16.3 W/m -°K | 20° |

| Pipe / Tube (SMLS) | Sheet / Plate | Bar | Forging | Fittings |

| A 213 | A 240, A 666 | A 276 | A 182 | A 403 |