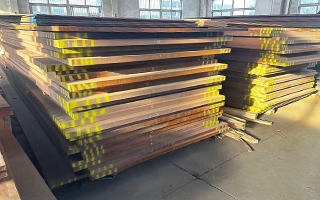

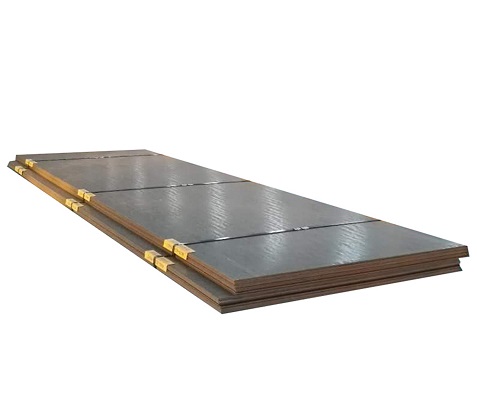

EN High strength structural steel

EN High Strength Structural Steel is commonly used in various industries, including construction, engineering, automotive, and transportation. It is favored for its ability to withstand heavy loads, resist impact and fatigue, and maintain structural stability even under challenging conditions. The enhanced strength of these steels allows for the design of lighter and more efficient structures, resulting in cost savings and improved energy efficiency.

| EN High Strength Structural Steel Grades |

Designation |

Typical Applications |

| S355JR |

EN 10025-2 S355JR |

Structural components, bridges, buildings |

| S355J0 |

EN 10025-2 S355J0 |

Construction machinery, bridges, towers |

| S355J2 |

EN 10025-2 S355J2 |

Offshore structures, cranes, shipbuilding |

| S355K2 |

EN 10025-2 S355K2 |

Construction equipment, heavy machinery |

| S460N |

EN 10025-3 S460N |

Steel structures, bridges, pressure vessels |

| S460M |

EN 10025-4 S460M |

Offshore structures, wind turbines |

| S690QL |

EN 10025-6 S690QL |

Heavy lifting equipment, mining machinery |

| S890QL |

EN 10025-6 S890QL |

Bridges, lifting equipment, high-rise buildings |

| S960QL |

EN 10025-6 S960QL |

Crane booms, transport equipment, steel frames |

.jpg)

Multi-Grade EN High strength structural steel

In addition to the grades in the table, the commonly used EN High Strength Structural Steel grades are:

S355J2, S420MC, S460MC, S500MC, S550MC, S700MC, S960QL, S1100QL, S1300QL, S235JRH, S275JOH, S355JOH, S355JOH,S420nh, S460nlh, S500ql1, S550ql1, S690ql1, S890ql1,S960QL1, etc. These grades offer a variety of strength, toughness and impact resistance properties, allowing the appropriate grade to be selected for specific engineering requirements. Whether used in construction, bridges, heavy machinery or other structural applications, these grades provide reliable high strength support.

These EN High Strength Structural Steel grades undergo rigorous quality control and mechanical properties testing during the manufacturing process to ensure they meet the requirements of European standards.

Key Features:

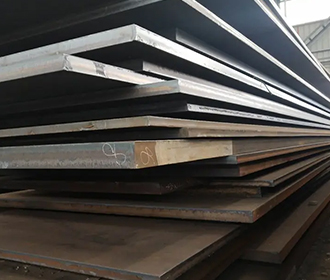

EN High Strength Structural Steel grades offer a wide range of mechanical properties, allowing engineers and designers to select the most suitable grade based on specific project requirements. These properties include high tensile strength, excellent toughness, good weldability, and improved corrosion resistance.

Furthermore, EN High Strength Structural Steel can be further processed and fabricated to meet specific design needs, such as cutting, bending, welding, and forming. This versatility makes it highly adaptable to various structural applications, including bridges, buildings, offshore platforms, heavy machinery, and infrastructure projects.

Overall, EN High Strength Structural Steel offers a combination of strength, durability, and versatility, making it an ideal choice for demanding applications that require superior performance and long-lasting structural integrity.

Corporate Environment:

.jpg)

.jpg)