Chemical Composition

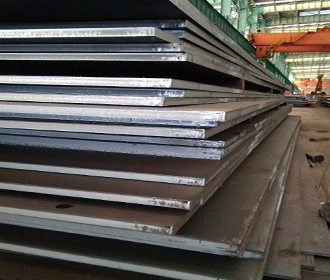

Q235D carbon steel plate, high-strength steel plate is widely used in construction, automobile, shipbuilding, machinery and equipment and many other industries, but high-strength steel plate must be properly selected. First of all, the grade is too high, which means that the price will be high due to the high manufacturing cost. Secondly, a low level means that the safety performance is not up to standard. Third, the specifications of high-strength steel plates must be selected in strict accordance with the design drawings. Fourth, it is recommended to purchase commercial special equipment to test high-strength steel plates.

| Main chemical elements composition of Q235D |

| C |

Si |

Mn |

P |

S |

| 0.17 |

0.35 |

1.40 |

0.035 |

0.035 |

It has good toughness. By strictly controlling the chemical composition, reducing the content of harmful elements in Q235D carbon steel plate, and selecting reasonable heat treatment conditions, NM360 steel plate has good toughness. Therefore, high-reliability structural parts can be constructed according to the brittle failure of wear-resistant parts. Q235D carbon steel plate adopts advanced technology and equipment, combined with high and scientific technical management, so that the material and shape of the product are uniform and beautiful.

S355J2 steel plate Q235D carbon steel plate rolling process is a controlled rolling process. In the rolling process, the ingot rolling temperature is 1000-1050°C; The first stage adopts a low-speed large-scale reduction rolling process, the high-temperature stage is 950-1000 °C, the rolling speed is 1.6-2.0m/s, the single reduction rate of Q235D carbon steel plate is 15-20%, and the cumulative reduction rate is 40-45% to ensure the full deformation of the ingot. In the first stage, the starting rolling temperature is 910-930 °C, and the finishing rolling temperature is ≤ 870 °C.