Lethathamo la lihlahisoa

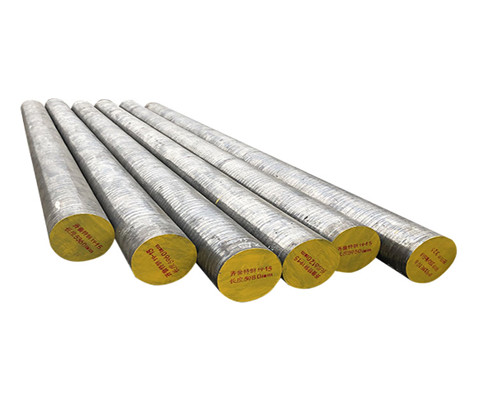

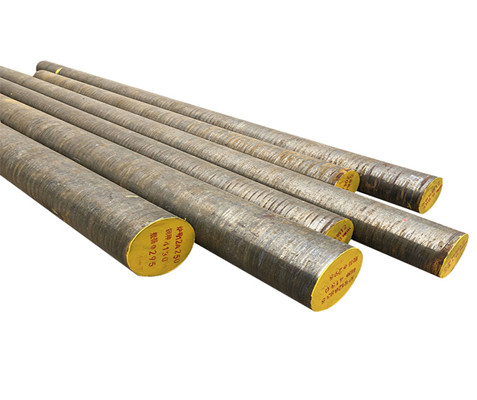

Litšepe, phepelo ea tšepe ho tloha leholimong ho ea leoatleng lia fumaneha, lia fumaneha lefatšeng ka bophara;

Iteanye le rona

Aterese: No. 4-1114,Beichen Building,Beicang Town,Beichen District Tianjin,Chaena.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)