DIN 30CrNiMo8 tšepe ke tšepe ea alloy e entsoeng bakeng sa ho etsa lihlahisoa tse entsoeng.

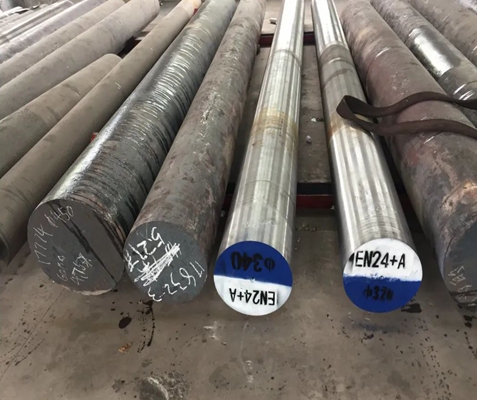

Hona joale Gnee e na le thepa e pota-potileng ea tšepe ea 30CrNiMo8 bakeng sa ho romelloa hang-hang ka boleng bo ka tšeptjoang le ho fumaneha ha bophara bo tloaelehileng. Bare e chitja e kentsoeng ka mocheso kapa e chesitsoeng ka mocheso e fumaneha ka bobeli. Lintlha tse ling tsa 30CrNiMo8 ke tsena:

1. Phatlalatso e fapaneng ea DIN 30CrNiMo8 Grade Steel

30CrNiMo8 Round Bar: bophara ba 20 ~ 130mm

Boemo: ho chesa ho pota; normalized; Q+T

2. Tlhaloso e nepahetseng bakeng sa 30CrNiMo8 Material

| EN 10083-3 | BS970 |

| 30CrNiMo8 / 1.6580 | 823M30 |

3. DIN 30CrNiMo8 Sebopeho sa Lik'hemik'hale

| MPHATO | MOTS'EOA CHEMEKE | |||||||

| C | Si | Mong | P | S | Kr | Mo | Ni | |

| max | max | max | ||||||

| 30CrNiMo8 / 1.6580 | 0,26 ~ 0,34 | 0,40 | 0,50 ~ 0,80 | 0,025 | 0,035 | 1,80 ~ 2,20 | 0,30 ~ 0,50 | 1,80 ~ 2,20 |

4. Thepa ea 30CrNiMo8

Modulus ea elasticity [103 x N/mm2]: 210

Boima ba 'mele [g/cm3]: 7.82

5. Ho etsoa ha DIN 30CrNiMo8 Alloy Steel

Mocheso oa ho etsa mocheso: 1050-850oC.

6. Kalafo ea Mocheso

Chesa ho 650-700oC, pholile butle. Sena se tla hlahisa boima bo phahameng ba Brinell ba 248.

Mocheso: 850-880oC.

Ho thatafala ho tloha mocheso oa 830-880oC o lateloa ke ho tima oli.

Mocheso oa mocheso: 540-680oC.

7. Likopo tsa 30CrNiMo8 Round Bar

Bakeng sa lisebelisoa tse hatelitsoeng ka ho sa feleng tse nang le likarolo tse kholo tsa sefapano bakeng sa boenjiniere ba likoloi le mechine. Bakeng sa ts'ebetso ea moruo tlas'a khatello e matla e matla, likarolo li tlameha ho etsoa bakeng sa matla kapa boima bo boholo.