| Sebopeho sa Lik'hemik'hale (%) | |||||||

| Kereiti ea tšepe | C | Si | Mong | V | Kr | Mo | |

| 25Cr2MoVA | 0.22~0.29 | 0.17~0.37 | 0.40~0.70 | 0.15~0.30 | 1.50~1.8 | 0.25~0.35 | |

| Matla a tlhahiso σs/MPa (>=) | Matla a thata σb/MPa (>=) | Elongation δ5/% (>=) |

Phokotso ea sebaka ψ/% (>=) |

| ≧785 | ≧930 | ≧14 | ≧55 |

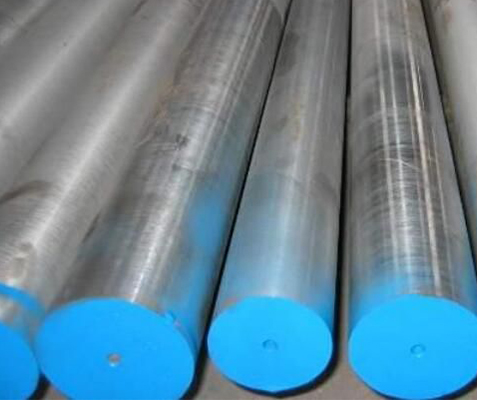

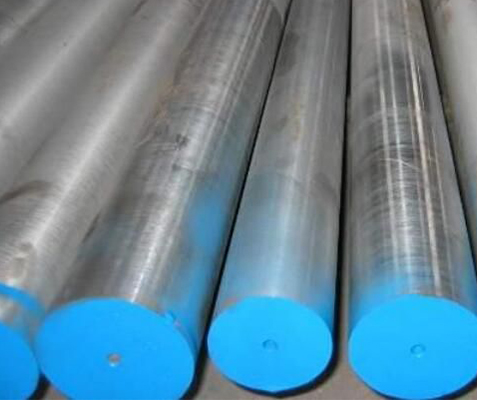

Re ka hlahisa 25Cr2MoVA e na le lintlha tse latelang:

Tšepe ea bar e chitja: 1mm ho isa ho 3000mm

Tšepe ea sebopeho se sekwere: 1mm ho isa ho 2000mm

Plate tšepe: 0.1mm ho 2500mm

Bophara: 10mm ho isa ho 2500mm

Lenth: Re ka fana ka lente efe kapa efe ho latela se hlokoang ke moreki.

Ho qhekella: Lishafi tse nang le mapheo/lipeipi/li-tubes/slugs/donuts/cubes/libopeho tse ling

Liphaephe: OD: φ6-219 mm, le botenya ba lebota ho tloha ho 1-35 mm.

Boemo ba thepa e feliloeng: hot forging/hot rolling + annealing/normalizing + tempering/ho tima + ho halefisa/maemo afe kapa afe a ipapisitseng le tlhoko ea moreki.

Maemo a ka holim'a lefatše: scaled (hot working finish)/ground/machine e sa sebetseng/machining a matle/ho ipapisitse le tlhoko ea moreki.

Lisebelisoa tsa ho sebetsa ka metallurgical: electrode arc + LF/VD/VOD/ESR/Vacuum consumable electrode.

Tlhahlobo ea mahlale: 100% tlhahlobo ea ultrasonic bakeng sa ho se phethahale hofe kapa hofe kapa ho ipapisitsoe le se hlokoang ke moreki Litšebeletso tse ntle haholo bakeng sa mefuta eohle ea liindasteri, ka melemo ea theknoloji, lisebelisoa le theko.

Re o sebeletsa ka botshepehi, botshepehi le botsebi ba rona.